Millet Processing Machinery

Represented by Ameejee Valleejee & Sons (Pvt.) Ltd. in Pakistan

Batch recirculation grain dryer

It can be equipped with a variety of heat sources for heating, low-temperature sufficient drying, maximizing heat exchange efficiency, and minimizing environmental load.

Cylindrical pre-cleaner

Longer sieve cylinder for cleaner sieving.

Planar rotary cleaning sieve

Three movement trajectories are generated on the same screen body. The approximate left and right shaking at the feed end of the screen body is conducive to uniform feeding and automatic grading.

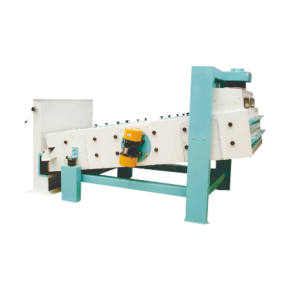

Vibratory cleaning sieve

All-in-one functionality, effectively removing light debris, dust, large debris, and small debris.

Vibration cleaning sieve

The vibration angle and screen inclination angle are adjustable, with high grading efficiency, high throughput, low consumption, hygiene, and environmental protection.

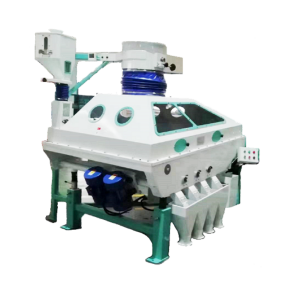

Suction specific gravity destoner

Suitable for removing stones from raw materials and finished products. The process is stable, with good stone grading and removal effects. The unique screen structure results in lower energy consumption, and the negative pressure suction prevents dust from being dispersed.

Single-layer suction vibration destoner

Utilizing two vibration motors as vibration sources, the screen body amplitude motor angle is adjustable, and the structural design is more reasonable; there is no dust dispersion, it is sturdy and durable, and it is easy to disassemble, maintain, and clean.

Corn suction specific gravity selecting machine

High purity separation of germ and corn grits, with the added function of destoning, achieving the effect of one machine with multiple uses.

Cyclone separator

Using a light miscellaneous spiral conveyor and a light miscellaneous axial pressure gate closing and exclusion mechanism improves the phenomenon of poor closing.

Circular suction separator

Large suction area, energy-saving, good wind selection effect.

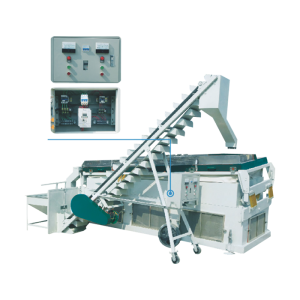

Specific gravity machine selection machine

Remove moldy grains, water-soaked grains, shrunken grains, broken grains, sprouted grains, insect-damaged grains, and grains infected with Fusarium, as well as other lighter impurities.

Magnetic separator

Specialized high-intensity magnetic rollers are used at the feed end to easily remove materials with weak magnetic properties, such as soil clods, lightweight stones, and brick fragments.

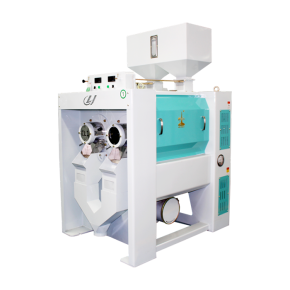

MLGQ series pneumatic rice milling machine

Intelligent Control: Siemens LOGO PLC is used for automatic control. Automatic pneumatic roller clamping upon material arrival and automatic pneumatic roller release upon material interruption; automatic material gate control; roller pressure can be linearly adjusted directly via the pressure gauge.

Intelligent pneumatic rice milling machine

Stepless speed control is achieved using variable frequency drive, with automatic timed switching between fast and slow rollers, enabling unattended operation.

Bean peeling machine

High-efficiency dehulling process with low raw material breakage rate.

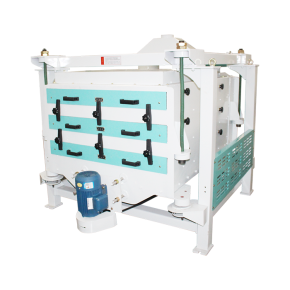

Double-weight gravity separator

It adopts a double-hull structure, runs smoothly, has a small impact on the supporting foundation, and has good consistency in the separation effect of the two sieves, with stable and reliable performance.

Single gravity separator screen

Unique speed control device and feeding device, more stable process performance, with an external glass dust cover for a beautiful and dust-free appearance.

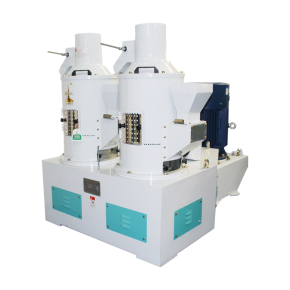

Vertical air-jet iron roller polishing machine

Compared with horizontal hulling and milling machines, this series of vertical models features better hulling and milling uniformity and higher rice yield.

Vertical air-jet iron roller polishing machine

The grinding room adopts a bottom-in, top-out feeding method, with multiple units connected in series. No elevator is needed in between, resulting in a small footprint. The material flow direction can be from left to right or from right to left.

Vertical sand roller grinder

The grinding room adopts a bottom-in, top-out feeding method, with multiple units connected in series. No elevator is needed in between, resulting in a small footprint. The material flow direction can be from left to right or from right to left.

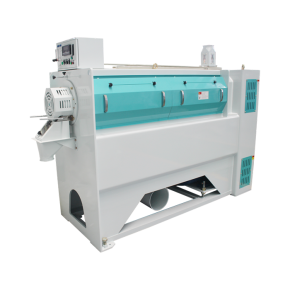

Horizontal air-jet sand roller grinder

Using sand rollers with a high length-to-diameter ratio results in a larger grinding area and a more uniform grinding effect.

Recumbent polisher

By further polishing the already milled grains, removing some of the surface skin, bran, and impurities, a bright and clean appearance is achieved, improving the grain’s marketability.

Planar rotary particle classifier

Rice is graded into whole rice, large broken rice, and small broken rice according to the size of the rice grains and broken rice pieces.

Double-layer particle screening

The screen body uses a universal joint flexible suspension, the equipment runs smoothly, and the mechanical performance is stable.

Thickness grader

Materials are classified according to thickness and size.

Selected drum

Equipment for selecting broken rice grains from premium rice.

Gate

High-pressure pulse dust collector

A cylindrical enclosure is used, providing good overall rigidity and strength.

SEC series ultra-low speed bucket elevator

Improved low-speed performance, prevents broken rice grains.

MS/TDTG series ultra-low speed bucket elevator

Using a special guiding chute to reduce the breakage rate of rice grains.

Bucket elevator

The TDTG series bucket elevator is a fixed, continuous vertical conveying device suitable for the vertical lifting of granular or powdery materials.

Enchained scraper conveyor

Wide adaptability, suitable for conveying powdery, small granular, and small blocky materials.

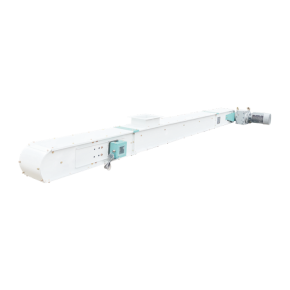

General scraper conveyor

Wide adaptability, suitable for conveying powdery, small granular, and small blocky materials.

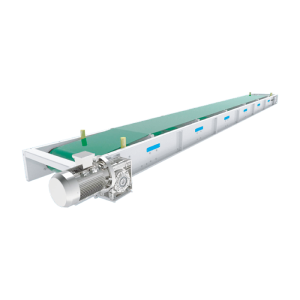

Belt conveyor

Suitable for bulk and packaged logistics conveying in various flow operations.

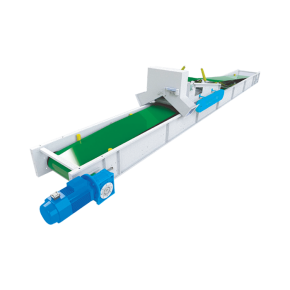

Belt conveyor with unloading car

High conveying capacity, long conveying distance, simple structure and easy maintenance. Low energy consumption and low operating cost.