Flygt Adaptive Mixers

Represented by Ameejee Valleejee & Sons (Pvt.) Ltd. in Pakistan

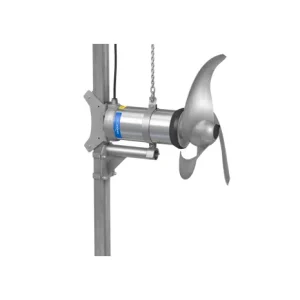

4200 Compact Adaptive Mixer Series

Product Features

- High-efficiency IE4 equivalent motor

- Integrated power electronics that eliminate the need for external Variable Frequency Drives (VFD)

- With 3 propeller sizes of of 370, 580 and 770 mm that have optimized and fixed blade angle

- Variable output (thrust) with speed ranging from 290 to 800 rpm

- Scalable mixer control system with flexibility to match different process scenarios

- Tank-side or remote control by adding FPG 415 gateway with analog I/O and fieldbuses

- Easy to upgrade to flexible mixer control (ADF-system). The mixer stays the same, independent of control system.

- Easy to install for mixer replacement installations

- Consistenly correct propeller rotation

- Soft start and stop

- Automatic overload protection

- Power factor close to 1

- Full status and alarms information for flexible control (ADF-system)

- Jog wheel operator panel FOP 315, or touch screen operator panel FOP 402 (option for ADF-system)

Read More

General Description

With its ability to adjust the output to the real demand, Xylem’s Flygt 4200 compact adaptive mixer series revolutionizes the wastewater treatment industry by bringing complete control and adaptability into the mixing process. The AD standard control system with pre-set control incorporates many built-in valuable features providing large energy savings, key autonomous protection capabilities and scalability for flexible control functionality (ADF-system). Ease of connectivity and connections to the operator panel allow fully integrated monitoring functions, so you can be assured of optimal mixer operation wherever you may be.

Downloads

4320 Geared Adaptive Mixers

Product Features

- High-efficiency permanent magnet IE4 equivalent motor

- Integrated power electronics based on the Flygt Dirigo technology that eliminate the need for external Variable Frequency Drives (VFD)

- Large diameter propeller (up to 2,5 m) with backswept self-cleaning design

- Geared and adjustable output (thrust) with speed up 70 rpm

- Scalable mixer control system with flexibility to match different process scenarios

- Tank-side or remote control by using FPG 415 gateway with analog I/O and fieldbuses (ADF-system)

- Automated control for oxidation ditch processes by using pre-engineered controller APP 412 with analog I/O and fieldbuses (ADC-system)

- Full status and alarms information for flexible or automated control (ADF and ADC-system) by using jog wheel operator panel FOP 315 or touch screen operator panel FOP 402

- Multiple mixer control with APP 412 (ADC system)

- Easy to upgrade to flexible- or automated mixer control (ADF or ADC system). The mixer is always the same independent of control system.

- Consistently correct propeller rotation

- Soft start and stop

- Automatic overload protection

- Power factor close to 1

Read More

General Description

Whether you operate Flygt 4320 with full automation or manage it from the tank-side or your control room, it provides market leading mixing efficiency with significant energy savings. By continuously matching output to real process demand without compromising mixing efficiency, it generates up to 50 % in energy savings and lower the overall operational cost.

Downloads