Air Treatment Solutions

Represented by Ameejee Valleejee & Sons (Pvt.) Ltd. in Pakistan

Compressed air treatment is not just about removing moisture and contaminants — it is about protecting equipment, reducing downtime, and ensuring compliance with environmental standards. Atlas Copco, represented in Pakistan by Ameejee Valleejee & Sons (Pvt.) Ltd., offers a comprehensive range of air treatment solutions designed to complement compressors and dryers, ensuring that every part of the compressed air network delivers performance, reliability, and sustainability.

Read More

One of the key elements in air treatment is condensate management, and Atlas Copco’s OSC Condensate Management Systems provide an efficient, environmentally friendly method of separating oil from water in condensate before discharge. This ensures compliance with environmental regulations while minimizing operational costs.

To further protect the network, WSD Water Separators are installed to efficiently remove bulk water droplets from compressed air systems. By eliminating the majority of liquid water early in the treatment process, they reduce the burden on downstream dryers and filters, thereby enhancing overall system reliability.

For automatic and hassle-free removal of condensate, Atlas Copco offers several drain solutions. The WD Automatic Drains are robust, mechanical units that reliably discharge condensate without wasting compressed air. For more advanced monitoring, EWD Electronic Drains use intelligent controls and level sensors to discharge condensate precisely when required, eliminating energy loss and ensuring optimal efficiency. Where simple and economical operation is needed, the TWD Timer Drains provide time-based discharge control, offering flexibility in less critical applications.

Completing the portfolio are Atlas Copco’s HD and TD Aftercoolers, which play a vital role in reducing the temperature of compressed air immediately after compression. By cooling the air and condensing moisture, these aftercoolers improve downstream drying and filtration efficiency, reduce corrosion risks, and extend equipment life.

Together, these air treatment products form a complete solution that not only safeguards compressed air systems but also ensures environmental compliance, energy efficiency, and long-term operational reliability.

OSC 12-2500 oil-water separator

OSC series

Too many oil-water separators offer subpar quality and minimal ease of use. No more! Atlas Copco’s OSC allows you to comply with local regulations and to protect the environment with unmatched filtration precision and zero-hassle maintenance.

Description

The OSC stands for:

Oil is separated more effectively thanks to innovative dual-stage filtration technology

Strict clean water standards pose no problem because the OSC delivers extremely high purity

Cartridges and filter bags that capture the filtered oil make condensate treatment easier and a lot less messy

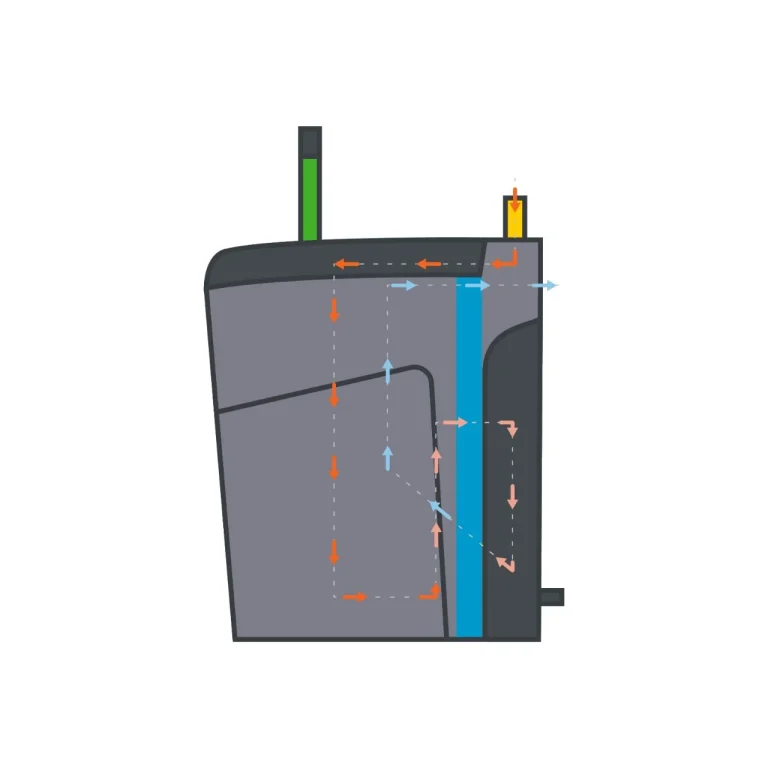

The benefits of dual filtration

The OSC uses an ingenious triple filtration technology with polypropylene and activated carbon that removes a wider range of oil types and can achieve a water purity as low as 5 ppm. Organoclay cartridges are available to take on stronger emulsions.

To optimize its performance, the OSC monitors correct water passage and polypropylene filter saturation. A test outlet simplifies verification of filtration performance.

Technical benefits

A complete range

The OSC comes in different types and sizes to give you maximum flexibility. There are small single-use and larger serviceable models. The OSC 12-625 are two-stage, while the OSC 1250-2500 are three-stage units. For the OSC 2500, a flow divider evenly splits the flow between two units.

Effortless maintenance

The OSC comes with multiple smaller polypropylene bags for our larger units and easy removeable activated carbon and organoclay cartridges. This simplifies maintenance and reduces service time.

And one more bonus

The OSC’s user-friendliness also extends to its extremely long service interval of 4,000 hours, which ensures optimal uptime.